Allup Silica Limited (ASX: APS) (“Allup” or “Company”) is pleased to provide an update on works to progress development of its 100%-owned McLaren Valuable Heavy Mineral Sands (VHMS) Project near Balledonia, WA.

Summary

- IHC Mining Consultants (IHC) has commenced initial stages of McLaren Mineral Sands Pre-Feasibility Study (PFS) engineering design

- Initial design Scope based on 10Mtpa throughput to produce up to 400,000tpa ilmenite product

- Previous metallurgical test work completed by IHC Competent Persons in 2018 demonstrates good ilmenite recoveries from a conventional mineral sands flowsheet

- Allup plans to commence infill drilling program at McLaren in Q4, 2024

- Environmental Resources Management (ERM) appointed to plan infill drilling program and update Mineral Resource Estimate (MRE) once drilling results are received.

- PFS expected to be completed during Q2 2025

Allup is also preparing a drilling program for the project in Q4 CY24 to enable an update of the existing Mineral Resource Estimate (MRE) in early 2025, and to investigate potential to increase the known resource.

Previous IHC Metallurgical Testwork Results

In 2018, IHC completed a metallurgical testwork program on a representative sample derived from a 14-tonne bulk sample from the McLaren deposit. The sample assayed approximately 7.2% heavy mineral. Mineralogical analyses of the heavy mineral indicate it to contain 56.3% ilmenites and higher grade titanium minerals such as Leucoxene.

The IHC metallurgical test work program confirmed the material to be amenable to standard mineral sands processing methodologies, utilising typical mineral sands equipment.

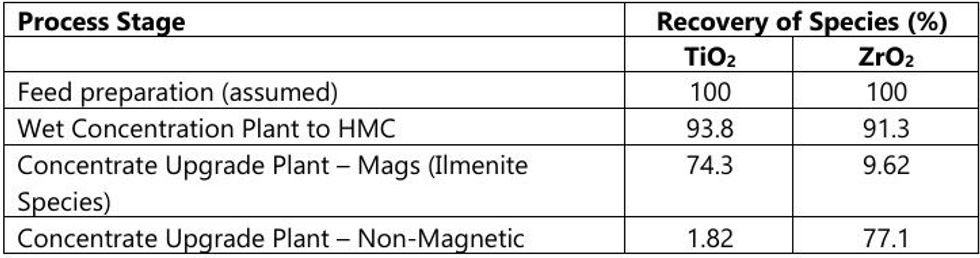

Table 1: Results from IHC testwork completed in 2018

Ilmenite recovery from WCP feed into the CUP Magnetic stream was ~75% of ilmenite, Altered Ilmenite and HiTi minerals. Overall recovery of rutile/anatase from the WCP feed into the non-magnetic concentrate was ~57% Overall recovery of zircon from the WCP feed into the CUP non-magnetic concentrate was ~70%.

Slimes settling was achieved using addition of 3% gypsum, resulting in significant improvement in flocculant dosing rates, down to 150-200g/t.

The test work produced final products of:

- Ilmenite of a suitable grade to be classified as sulphate ilmenite

- Rutile of a typical quality with 95.7% TiO2, 1.49% Fe2O3,

- Zircon of a typical standard zircon quality, noting levels of U + Th at 265ppm were considered very low.

Flowsheet Development

The IHC 2018 test work resulted in the development of a conceptual flowsheet using traditional mineral sands separation techniques. It consisted of three circuits, comprising:

- Feed Preparation – made up of hydrocyclones and a thickener used to settle and separate the slimes. The slimes fraction would be returned to the mining void along with the tails stream. The non-slimes portion would be fed to the WCP.

- Wet Concentration Plant (WCP) – made up of several spiral stages (gravity separation) – the WCP process produced a Heavy Mineral Concentrate (HMC) containing 89.1% heavy mineral, 25.9% TiO2 and 0.37% ZrO2.

- Concentrate Upgrade Plant (CUP) – screening to remove +425 µm material (determined by test work to be barren), then several stages, primarily of magnetic separation.

The HMC produced in the WCP was processed through the CUP to produce a magnetic concentrate suitable for an ilmenite process circuit and a non-magnetic concentrate containing 90-95% Heavy Mineral.

Click here for the full ASX Release

This article includes content from Allup Silica Limited, licensed for the purpose of publishing on Investing News Australia. This article does not constitute financial product advice. It is your responsibility to perform proper due diligence before acting upon any information provided here. Please refer to our full disclaimer here.

Credit: Source link